While the spotlight often shines on designers and models, the true architect-cum-partners of the fashion industry’s transformation are the textile chemicals as well. Working diligently behind the scenes, these substances are the catalysts that convert raw fibers into the stylish and functional garments we wear every day. From the vibrant hues of a summer dress to the wrinkle-free finish of a business shirt, textile chemicals are indispensable in every stage of production. This article examines the multifaceted arena of types of textile chemicals, highlighting the different categories of these substances and their particular uses. These substances are critical for achieving desired aesthetic and performance properties in fabrics.

Table of Contents

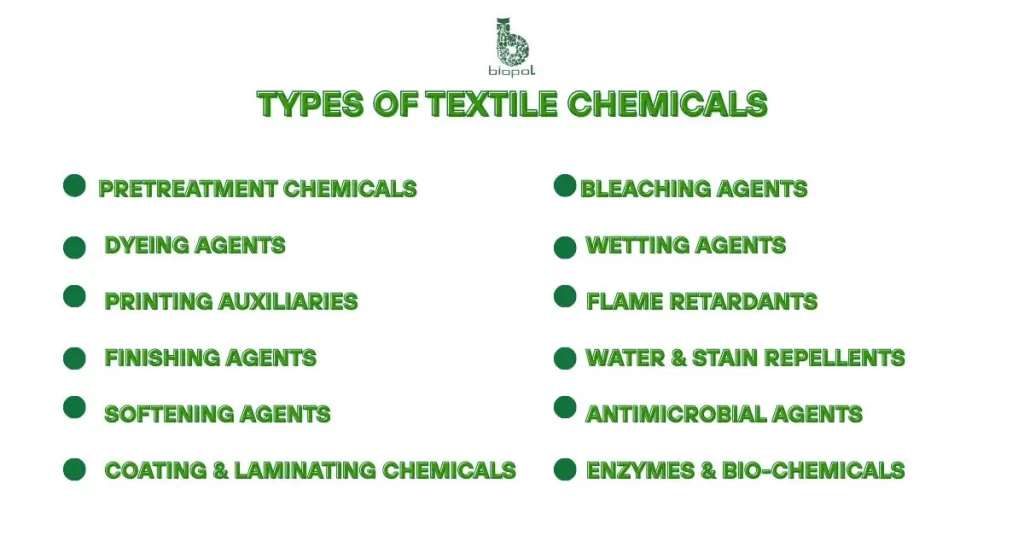

Based on Usage in Stage of Production

Pre-Treatment Chemicals

Before fabrics can be transformed into stunning garments, they need to undergo a series of pre-treatment processes to ensure optimal performance and appearance. This critical stage involves a diverse range of substances, and understanding the types of textile chemicals used in pre-treatment is essential. These chemicals play a vital role in removing impurities, preparing the fibers for subsequent dyeing and finishing processes, and ultimately impacting the quality and longevity of the final product.

Key chemicals in the pre-treatment phase

- Scouring Agents: These chemicals remove natural impurities like waxes, oils, and dirt from fibers, improving their affinity for dyes and enhancing their overall quality.

- Bleaching Agents: Bleaching agents, such as hydrogen peroxide and sodium hypochlorite, are used to whiten fibers, making them more receptive to dyes.

- Desizing Agents: These chemicals serve to eradicate sizing agents that are applied to yarns in order to improve their properties for weaving and knitting.

By effectively preparing fabrics through pre-treatment, we set the stage for creating high-quality, durable, and aesthetically pleasing textiles.

Dyeing Chemicals

Once fabrics have been pre-treated, the next step is to infuse them with color. Dyes, the heart of this process, are chemical compounds that bond with fibers, imparting a wide range of hues.

Main Categories of Dyes Commonly Found in Textile Industry

- Reactive Dyes: The covalent bonding of these dyes with cellulose fibers ensures excellent color retention. They’re widely used for cotton and other cellulosic fabrics.

- Disperse Dyes: These dyes do not dissolve in water; however, they can break down into small particles capable of infiltrating synthetic fibers such as polyester and nylon.

- Acid Dyes: Acid dyes are applied to protein fibers like wool and silk in acidic conditions. An ample variety of shades is offered, featuring commendable resistance to fading.

- Basic Dyes: These cationic dyes have affinity for anionic fibers like acrylic. They produce bright, vibrant colors.

- Vat Dyes: While vat dyes do not dissolve in water, they can be altered into a soluble form that facilitates the dyeing process. They offer excellent colorfastness to light, washing, and chlorine.

By carefully selecting the right dye and optimizing the dyeing process, textile manufacturers can create stunning and durable colored fabrics.

Printing Chemicals

Printing functions as a means to create intricate designs and patterns onto textile fabrics. It involves the use of various chemicals, including dyes, pigments, and binders.

Printing Techniques and Chemicals Involved

- Screen Printing: This technique employs a mesh screen that incorporates a design to facilitate the application of ink onto the fabric.

- Rotary Screen Printing: A cylindrical screen is used to print designs onto fabric, allowing for high-speed production.

- Digital Printing: The process of digital printing employs inkjet technology to print images straight onto textiles.

To achieve prints of exceptional quality, marked by vibrant colors and distinct details, the application of printing chemicals is indispensable. By understanding the science behind printing, we can appreciate the artistry and technology that goes into creating beautiful and intricate designs on textiles.

Finishing Chemicals

The final stage of textile production, Finishing, involves a range of chemical treatments to enhance the fabric’s appearance, feel, and performance. These finishing substances confer valuable properties, including softness, the ability to resist wrinkles, water repellency, and flame retardancy.

Key Finishing Chemicals and their Functions

- Softeners: The use of softeners improves the sensory experience of fabrics, leading to enhanced comfort for individuals wearing them. They can be applied to various fibers, including cotton, polyester, and wool.

- Water Repellents: These agents generate a shielding barrier on the fabric’s surface, obstructing water from penetrating and preserving the fabric’s dryness.

- Wrinkle-Resistant Finishes: These finishes are engineered to decrease the propensity of fabrics to crease, facilitating easier care.

- Flame Retardants: Flame retardant chemicals are used to treat fabrics to reduce their flammability, making them safer for use in various applications.

- Antimicrobial Finishes: These surface treatments restrict the development of bacteria and fungi, which helps to decrease unpleasant odors and avert the spread of illnesses.

By carefully selecting and applying finishing chemicals, textile manufacturers can create fabrics that meet the specific needs of consumers, from performance wear to luxury apparel.

Auxiliary Chemicals

Auxiliary chemicals are the hidden heroes of the textile industry, playing a vital role in supporting various stages of textile production. These chemicals work in conjunction with dyes, finishes, and other chemicals to optimize the overall process.

Types of Auxiliary Chemicals:

- Surfactants: Surfactants reduce surface tension, improving wetting, detergency, and emulsification properties. These materials are utilized throughout various steps of textile processing, encompassing scouring, dyeing, and finishing.

- Leveling Agents: Leveling agents promote even dye distribution, preventing color streaking and shading. They are particularly important in dyeing processes to achieve consistent color.

- Dispersing Agents: Dispersing agents prevent particles from agglomerating, ensuring uniform dispersion in dyeing and finishing processes.

- Oxidizing and Reducing Agents: These chemicals find application in multiple textile processes, such as bleaching, dyeing, and printing. They help to oxidize or reduce chemical compounds, facilitating specific reactions.

For a more in-depth explanation about Chemical Auxiliaries, read our detailed blog on Textile Chemicals and Auxiliaries

Based on Purpose

Specialty Chemicals

The textile sector is in a state of continuous transformation, propelled by consumer preferences for innovative, high-performance, and sustainable materials. Specialty chemicals play a crucial role in meeting these demands, offering advanced solutions to address specific challenges and enhance the overall quality of textiles.

Examples of Specialty Chemicals

- Nano-Finishes: These cutting-edge technologies involve the application of nanomaterials to fabrics, imparting properties like water repellency, stain resistance, and UV protection.

- Bio-Based Chemicals: Sourced from renewable resources, bio-based chemicals provide a more environmentally friendly alternative to traditional petrochemical products. They are applicable in a variety of textile functions, including dyeing, finishing, and sizing.

- Smart Textiles: Specialty chemicals enable the creation of smart textiles that can respond to environmental stimuli, such as temperature and humidity. These innovative fabrics have applications in sportswear, medical textiles, and wearable technology.

- Functional Finishes: These finishes impart specific functional properties to fabrics, such as flame retardancy, antimicrobial protection, and anti-static properties.

By leveraging specialty chemicals, the textile industry can create innovative and sustainable products that meet the needs of modern consumers.

Technical Textile Chemicals

Technical textile chemicals play a vital role in enhancing the performance, durability, and functionality of textiles used in specialized applications like healthcare, construction, automotive, and defense. These chemicals are formulated to meet high-performance standards, offering resistance to extreme conditions, environmental exposure, and mechanical stress. They enable fabrics to perform beyond aesthetics, ensuring they meet the demanding needs of technical and industrial sectors.

Examples of Technical Textile Chemicals

- Flame Retardants: Improve fire resistance in fabrics used in protective clothing and furnishings.

- Water Repellents: Create hydrophobic surfaces for outdoor and sportswear textiles.

- UV Stabilizers: Protect fibers from degradation due to prolonged sun exposure.

- Antimicrobial Agents: Inhibit bacterial and fungal growth in medical and hygiene textiles.

- Anti-Static Agents: Reduce static charge buildup in electronic and cleanroom textiles.

- Coating Agents: Add extra strength, flexibility, or impermeability to industrial fabrics.

- Conductive Chemicals: Allow fabrics to conduct electricity for smart textiles and wearable tech.

- Soil and Stain Repellents: Maintain cleanliness and appearance in automotive and upholstery textiles.

Technical textile chemicals are crucial in tailoring fabric properties to specific technical requirements, ensuring safety, efficiency, and longevity in end-use applications.

Concentrated Textile Chemicals

Concentrated textile chemicals are high-performance solutions formulated to deliver maximum effectiveness with minimal usage. These chemicals enhance efficiency in processes like pretreatment, dyeing, finishing, and washing, while significantly reducing water, energy, and transportation costs. Their compact nature supports sustainable manufacturing by minimizing environmental impact and storage space. Ideal for modern textile operations, concentrated chemicals ensure consistent results, cost savings, and improved process control.

Examples of Concentrated Textile Chemicals

- Concentrated wetting agents

- High-efficiency detergents

- Low-foam scouring agents

- Multifunctional softeners

- Eco-friendly dyeing auxiliaries

- Concentrated finishing agents

- Enzyme-based bio-polishing solutions

Textile Chemicals Modifier

Textile chemicals modifier is a specialized agent used to alter or enhance the properties of fabrics during processing. These modifiers improve performance characteristics such as softness, strength, absorbency, and dye affinity. They are essential in optimizing textile behavior for specific end-uses, ensuring better quality, functionality, and aesthetics. By tailoring fabric properties, chemical modifiers support innovation in fashion, home textiles, and technical fabrics while promoting process efficiency and sustainability.

Examples of Textile Chemicals Modifier

- Silicone-based softeners

- Anti-static agents

- Hydrophilic finish modifiers

- Flame retardant additives

- Anti-pilling agents

- Crosslinking agents

- UV-resistant coatings

- Stiffening modifiers

Besides the above two main categories, one can also take a look at Construction & Textile Chemicals article to understand how these closely related chemical types, though belonging to different industries, work.

Conclusion

Types of Textile Chemicals play a crucial yet often overlooked role in the fashion industry, fostering innovation and influencing the future of textile development. From traditional dyeing and finishing techniques to cutting-edge technologies, these chemicals play a crucial role in creating high-quality, functional, and sustainable fabrics. As the textile industry advances, the landscape of textile chemicals will also adapt and change. By embracing sustainable practices, investing in research and development, and collaborating with industry stakeholders, we can ensure a future where textile chemicals contribute to a more sustainable and innovative world.

Also Read: Textile Chemicals: The Secret Sauce Behind Your Clothes