Emerging Innovations in Textile Chemicals News Product are transforming the industry with cutting-edge technologies that enhance sustainability, functionality, and performance. From eco-friendly dyes to smart fabrics, these advancements are reshaping manufacturing processes and meeting consumer demands for sustainable, high-performance textiles, driving the future of fabric production worldwide.

Table of Contents

Innovations in Textile Chemicals

Emerging innovations in textile chemicals are revolutionizing the industry, transforming the way fabrics are created, worn, and disposed of. Key developments include:

- Sustainable Chemistry: Green solvents and biodegradable coatings are replacing traditional petroleum-based chemicals.

- Smart Textiles: The integration of nanomaterials is enabling fabrics to monitor health and adapt to weather conditions.

- Advanced Finishing Techniques: The adoption of plasma treatments and enzymatic processes is leading to lower water and energy use.

The result? A paradigm shift in the industry. Environmental footprints shrink, product lifespans extend, and consumer demands for both functionality and sustainability are met—without compromising on style.

As innovation continues to weave through tradition, textiles are no longer just fabrics; they are a reflection of the future.

Breakthrough Textile Products

Emerging innovations in textile chemicals are making headlines as they redefine the fabric of the textile industry. These changes are more than just minor improvements; they constitute a profound upheaval in the way textiles are made, treated, and understood.

- REVECOL® by ERCA TCS

- A standout in sustainable chemistry, REVECOL® transforms critical waste materials into high-performance textile auxiliaries. Certified by GRS, RCS, ZDHC, bluesign®, and GOTS, this product exemplifies how emerging innovations in textile chemicals can blend environmental responsibility with industrial efficiency.

- Devan Stain Release by Devan Chemicals

- Addressing the battle against stubborn stains, Devan Chemicals introduces a finishing technology that repels both oil- and water-based stains. This product highlights the industry’s commitment to delivering functional and sustainable solutions.

- BioBlack by Nature Coatings

- Challenging the dominance of petroleum-based dyes, BioBlack offers a carbon-negative, non-toxic alternative derived from wood waste. By lowering environmental impact without sacrificing performance, this innovation highlights the promise of new textile chemical advancements.

- Biopol Chemicals: ETP Decoloriser

- Biopol Chemicals introduces ETP Decoloriser, a highly effective polymer designed to decolorize wastewater in textile factories. This product helps reduce Chemical Oxygen Demand (COD) by up to 80%, providing instant action to improve wastewater quality. ETP Decoloriser is a cost-effective solution for textile manufacturers committed to sustainability. It promotes environmentally responsible practices while enhancing chemical performance.

- IR3000 Series Moisture Sensors by MoistTech Corp.

- Precision in moisture control is critical for textile quality. MoistTech’s IR3000 series employs Near Infrared (NIR) technology to provide real-time, non-contact moisture measurements, enhancing product consistency and energy efficiency.

- Eco-Advanced Indigo Dyeing by DyStar

- Revolutionizing denim production, DyStar’s new dyeing process significantly reduces energy consumption by up to 30% and water usage by up to 90%, setting a new benchmark for sustainable textile processing.

These innovations signal a broader trend toward sustainability, functionality, and efficiency in textile manufacturing. As emerging innovations in textile chemicals continue to evolve, they will reshape the industry, providing environmentally conscious and commercially viable solutions.

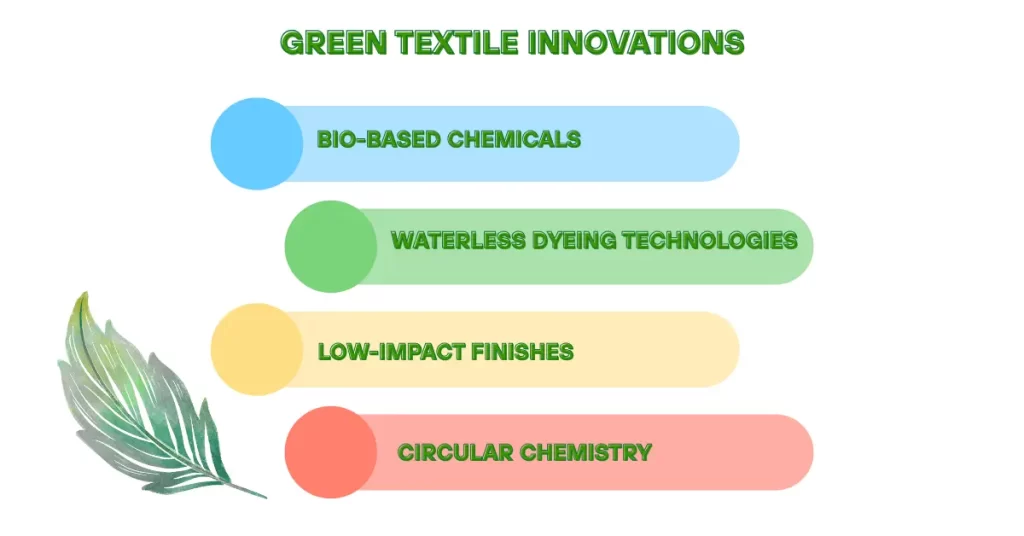

Green Textile Innovations

Emerging innovations textile chemicals news product are putting sustainability front and center, addressing the urgent environmental calls echoing across the textile industry. No longer a mere buzzword, sustainability is becoming the beating heart of modern chemical innovation.

What’s fueling this shift?

It’s a mix of consumer pressure, regulatory demands, and a deep industry realization: business as usual cannot continue. Emerging innovations textile chemicals news product are offering a way forward—without costing the Earth.

Key green advancements include:

- Bio-Based Chemicals: Sourced from renewable raw materials like corn, algae, and agricultural waste, these alternatives are steadily replacing fossil-derived counterparts.

- Waterless Dyeing Technologies: Supercritical CO₂ dyeing and digital pigment printing eliminate the need for vast amounts of water—a true game-changer for thirsty production processes.

- Low-Impact Finishes: Enzyme-based softeners, wrinkle-free treatments without formaldehyde, and natural antimicrobial agents are reducing chemical loads without compromising fabric performance.

- Circular Chemistry: Companies are developing textile auxiliaries and dyes designed to be easily extracted and reused, supporting closed-loop manufacturing.

The results? Fabrics that leave a lighter footprint, production lines that sip rather than guzzle resources, and brands that can finally walk the talk on eco-responsibility.

Sustainability is quickly evolving from an alternative approach to the primary route guiding the future of the textile industry.

For more in-depth insights into how smart textiles are changing the fabric of the industry, visit our article on news for textile chemicals. Learn about the cutting-edge materials that are pushing the boundaries of what’s possible in textile manufacturing.

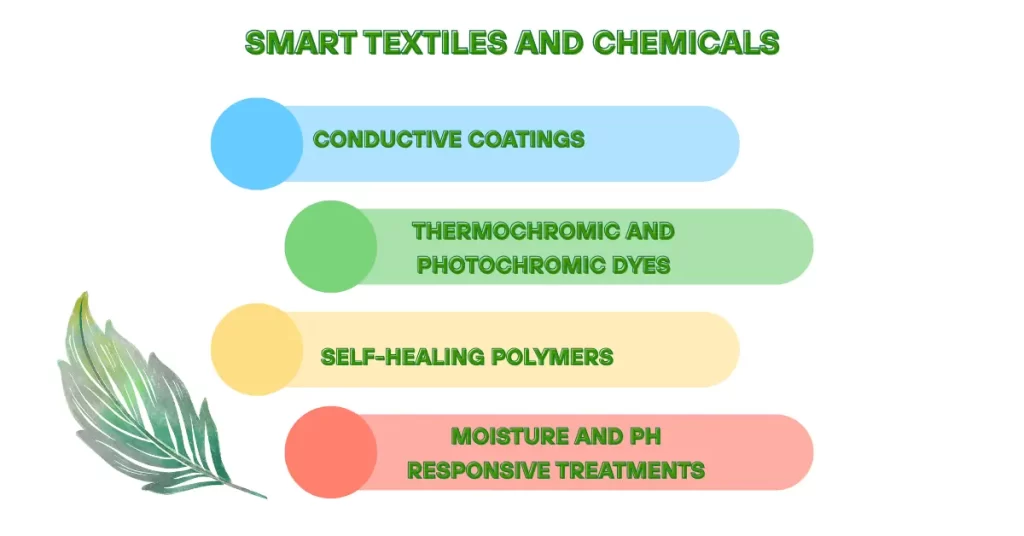

Smart Textiles and Chemicals

Intelligent textiles go beyond basic functionality, adapting to environmental changes and even monitoring health. Leading innovations in this space include:

- Conductive Coatings: Silver nanoparticles, carbon nanotubes, and graphene-based finishes are turning ordinary fibers into electronic components.

- Thermochromic and Photochromic Dyes: Fabrics now change color based on heat or sunlight exposure, creating dynamic clothing and responsive home textiles.

- Self-Healing Polymers: Chemical treatments allow textiles to repair small tears and punctures—almost like fabrics with a built-in first aid kit.

- Moisture and pH Responsive Treatments: Smart coatings enable textiles to sense environmental changes and adjust their properties accordingly, critical for sportswear and medical textiles.

Applications extend beyond fashion. Think medical monitoring shirts, military gear with adaptive camouflage, and automotive seats that track passenger vital signs.

In a world where intelligence is woven into every stitch, the line between textile and technology continues to blur—and the future looks remarkably well-dressed.

Innovations Driving Purchases

Emerging innovations in textile chemicals are no longer just scientific curiosities; they are key factors shaping buying decisions across the textile value chain. In today’s market, both consumers and brands expect every product to deliver performance, sustainability, and the latest technology.

Why does this matter? Because customer loyalty is now driven by innovation. Brands that showcase eco-friendly, smart-finished fabrics stand out in a crowded market.

Key drivers of buying decisions include:

- Sustainability: Certifications like GOTS, bluesign®, and OEKO-TEX® attract eco-conscious buyers.

- Functionality: Features like water-repellent, UV-protective, and temperature-regulating fabrics influence choices.

- Transparency: Brands using traceable, bio-based chemicals resonate with values-driven consumers.

- Cost Efficiency: Durable, high-performance textiles justify higher upfront costs due to longer lifespans.

For businesses, the strategy is clear: adopt innovations early, communicate benefits, and position products as modern solutions—not just commodities. In this competitive market, innovation is key.

FAQs:

Emerging Innovations in Textile Chemicals News Product

What chemicals are used in textiles?

Textile manufacturing relies on a range of chemicals to improve how fabrics function, how long they last, and how they look. Some common textile chemicals include:

- Dyes and Pigments: Used for coloring fabrics.

- Finishing Agents: Such as softeners, flame retardants, and water-repellent treatments.

- Sizing Agents: Used to improve fabric strength during weaving.

- Anti-crease Agents: To prevent wrinkles.

- Bleaching Agents: Used to whiten and remove natural color.

- Softening Agents: To make fabrics feel smoother and more comfortable.

- Coatings and Laminates: For waterproofing or enhancing performance.

What is an example of a smart textile product?

An example of a smart textile product is a health-monitoring shirt. These garments are embedded with sensors that monitor vital signs like heart rate, body temperature, or even blood pressure. The fabric adapts to the body’s needs, providing real-time data to a smartphone or wearable device, allowing users to track their health status seamlessly.

What is a smart material in textiles?

Smart materials in textiles refer to fabrics that can respond to external stimuli such as temperature, light, or moisture. These materials change their properties in response to environmental conditions. For example:

- Thermochromic Fabrics: Change color based on temperature.

- Shape Memory Alloys (SMAs): Allow fabrics to return to a predetermined shape after deformation.

- Conductive Textiles: Embedded with conductive fibers to interact with electronic devices or monitor the wearer’s health.

By enhancing fabric functionality, these smart materials open up novel application possibilities in healthcare, fashion, and sports.