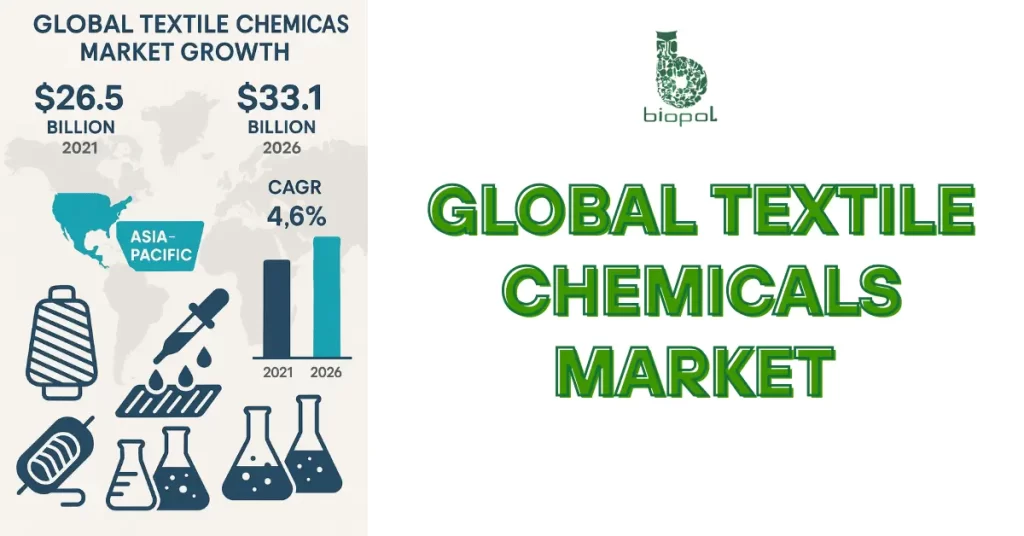

The textile chemicals market is witnessing significant expansion, with forecasts indicating a rise from USD 26.5 billion in 2021 to USD 33.1 billion by 2026. Driven by innovations in fiber technology, rising demand for sustainable solutions, and expanding applications in apparel, home textiles, and technical textiles, this market is evolving rapidly. As environmental concerns grow, manufacturers are embracing eco-friendly alternatives like low-VOC and biodegradable chemicals. This article provides insights into the trends, market dynamics, and future opportunities in the textile chemicals market.

Key Takeaways

- The textile chemicals market offers stable, mid-term growth, projected to reach USD 33.1 billion by 2026.

- Asia-Pacific dominance ensures scale advantages and long-term demand stability.

- Sustainability-driven regulations are creating high-margin opportunities in eco-friendly and bio-based chemicals.

- Rapid expansion of technical textiles is increasing demand for specialized, value-added chemical solutions.

- Companies investing in green chemistry, recycling technologies, and innovation are best positioned for above-average returns.

Textile Chemicals Market Overview

- In 2021, the global textile chemicals market was valued at USD 26.5 billion, with projections indicating it will rise to USD 33.1 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.6% during the period from 2021 to 2026. Read our detailed article on Global Textile Chemicals Business for more information.

- The textile chemicals market growth is primarily driven by increased demand for technical textiles, a segment that’s gaining traction due to their applications in sectors such as agriculture, automotive, and medical textiles. Check out our detailed article Sell Textile Chemicals on how to become a top Textile Chemicals seller and harness the tremendous demand.

- The implementation of low VOC (volatile organic compound) and biodegradable chemicals is anticipated to create profitable opportunities for market expansion in the years ahead.

Market Size and Growth Forecast (2024-2030)

| Year | Market Size (USD Billion) | CAGR |

| 2021 | 26.5 | – |

| 2026 | 33.1 | 4.6% |

| 2027 | 26.97 | 3.5%* |

*Note: The CAGR of 3.5% refers to a previous projection for 2020–2027.

- Asia-Pacific held 68.12% textile chemicals market share in 2019, driven by low labor costs and strong manufacturing hubs.

- The COVID-19 pandemic led to temporary interruptions; however, the long-term demand continues to be stable.

Key Market Segments

- Rapid expansion of technical textiles in sectors like agriculture, healthcare, and industrial manufacturing is fueling textile chemicals market demand.

- Consumers increasingly prefer functional and long-lasting textiles, boosting the need for advanced chemical treatments.

- Innovations in fiber and polymer chemistry are transforming textile performance, aesthetics, and sustainability.

- Heightened investment in textile R&D is enabling the development of custom chemical formulations tailored to specialized applications.

Market Breakdown by Product, Application & Region

| Segment | Key Insights |

| Fiber Type | Both natural fibers, such as cotton and wool, and synthetic fibers, including polyester and nylon, play a vital role in the market. |

| Product Type | Key categories include coating & sizing chemicals, colorants & auxiliaries, finishing agents, de-sizing agents, and surfactants. |

| Application | The market is influenced by textiles used in apparel, home textiles, and technical textiles (used in non-traditional applications like medical, construction). |

| Region | Asia Pacific dominates the market with a 68.12% market share followed by regions such as North America and Europe. |

Sustainability in Textile Chemicals

- The textile chemicals industry is undergoing a significant transition towards environmentally friendly formulations, influenced by consumer preferences and regulatory requirements.

- Low-VOC and biodegradable chemicals are gaining traction as manufacturers seek safer alternatives for both users and the environment.

- There’s growing momentum behind bio-based and low-toxic chemicals, with companies like Colorifix and Croda International pioneering sustainable dyeing technologies and bio-based surfactants.

- Technical textiles—especially in sectors like automotive, medical, and construction—are seeing rising demand for sustainable chemical finishes.

- The push for green chemistry is no longer optional; it’s becoming mandatory under stricter environmental regulations, particularly in Europe and North America.

- Innovation in dyeing is accelerating, with bio-based dyes increasingly replacing traditional synthetic dyes known for their health and environmental risks.

Regional Market Dynamics

- Asia Pacific leads the textile chemicals market, accounting for 68.12% of the global share in 2019, with key textile manufacturing hubs in China and India. Read our detailed blog on India Textile Chemicals Market : 4 Powerful Growth Factors for detailed information on Indian textile chemicals market conditions.

- North America and Europe are closely monitoring the situation, as a growing emphasis on sustainable production and environmentally friendly chemicals is driving market demand.

- Growing Regulations: Stricter environmental standards in developed regions are creating a demand for more sustainable chemicals.

Challenges in the Textile Chemicals Market

- Water Pollution: Wastewater generated from textile dyeing processes is a major environmental concern, with around 10-15% of dyes being released into water, causing pollution.

- Health Risks: Improper handling of chemicals found in dyes and various processing agents can lead to skin allergies, respiratory problems, and other health concerns.

- Regulatory Pressures: Stricter environmental regulations and sustainability goals are pushing manufacturers toward cleaner and safer alternatives in chemical processing.

Top Players in the Market

- BASF, Archroma, Biopol Chemicals Limited, and Huntsman are key players in the market, developing innovative bio-based chemicals and eco-friendly textile solutions. We, at Biopol Chemicals Limited, have our MARKETPLACE for you to make amazing deals on textile chemicals. Visit Today.

- Companies are focusing on providing sustainable alternatives, such as waterless dyeing technologies, to meet growing environmental concerns.

- Strategic partnerships, like Colorifix’s collaboration with Forster Rohner and Arvind in biological dyeing trials, showcase the industry’s push toward sustainability.

Tech Trends in Textile Chemistry

- The market is witnessing significant technological advancements with innovations in smart textiles and advanced coating technologies.

- Chemical recycling is gaining traction, particularly for synthetic fibers, to address growing concerns around textile waste.

- The rise of non-toxic chemicals and biodegradable textile finishes is opening up new avenues for market growth.

Investment Opportunities

- The growing demand for sustainable textile solutions presents lucrative opportunities for investors focusing on green chemistry and bio-based alternatives.

- The growth of technical textiles, fueled by innovation, is anticipated to yield substantial returns.

- Investment in advanced recycling technologies and eco-friendly manufacturing processes will continue to be a strong growth driver.

Conclusion

The future of the textile chemicals market is closely tied to sustainability and innovative chemical solutions.

Manufacturers must focus on developing eco-friendly chemicals, staying ahead of regulatory trends, and embracing new technologies to stay competitive.

The future expansion of the market will hinge on the effective incorporation of bio-based materials, sustainable methodologies, and cutting-edge textile processing technologies.

For a more in-depth analysis of the textile chemicals sector, please refer to our full textile chemicals market report, where we discuss the market’s future outlook and emerging trends.

FAQs

How big is the textile chemicals market?

The valuation of the global textile chemicals market stood at roughly USD 26.5 billion in 2021, and it is anticipated to expand to USD 33.1 billion by 2026, achieving a compound annual growth rate (CAGR) of 4.6%. The Asia-Pacific area continues to lead the market, supported by vigorous manufacturing activities and an increasing need for technical textiles.

What are the chemical products of the textile industry?

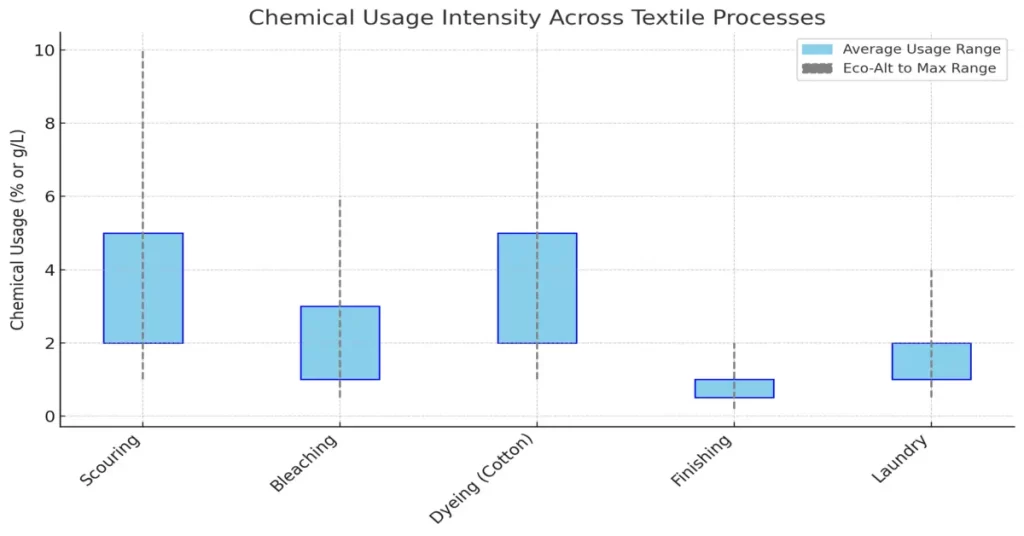

The textile industry relies on a wide range of chemical products including sizing agents, bleaching agents, dyeing and printing auxiliaries, finishing agents, surfactants, and colorants. These chemicals help modify the texture, color, durability, and performance of fabrics.

Which chemical is commonly used in the textile industry?

Common chemicals used in textile processing include sodium hydroxide (for scouring), hydrogen peroxide (for bleaching), acetic acid (for pH regulation), formaldehyde (for crease resistance), and various classes of dyes and pigments.

What is HCl used for in the textile industry?

Hydrochloric acid (HCl) is mainly used for pH adjustment, cleaning textile machinery, and neutralizing alkaline residues in different stages of textile processing.

What is the chemical name for cloth?

There is no single chemical name for cloth as it varies based on the fiber type. Natural fibers like cotton are made of cellulose, while synthetic fabrics like polyester are made from polyethylene terephthalate (PET), and nylon is made from polyamides.

Why are chemicals used in textiles?

In the textile sector, chemicals are vital for augmenting the visual appeal, durability, and utility of textiles.They play a key role in pre-treatment, dyeing, printing, finishing, and performance enhancement such as water resistance or flame retardancy.

Which acid is used in the textile industry?

Acetic acid is most commonly used for pH control in dyeing processes. Other acids like sulfuric acid (in rayon production) and hydrochloric acid (for cleaning and neutralization) are also used depending on the application.

Which chemical is used in laundry?

Laundry processes typically involve surfactants (detergents), sodium hypochlorite (bleach), optical brighteners, and enzymes for effective cleaning and stain removal.

Which chemical is used for dyes?

The types of dyes vary by fabric. Reactive dyes are used for cotton and cellulosic fibers, disperse dyes for polyester, acid dyes for wool and silk, and vat or azo dyes for high-performance applications.

Visit BIOPOL E-SHOP today for some amazing deals!!!

Also Read: Textile Chemicals: The Secret Sauce Behind Your Clothes