Surface chemical modification of textile fibres transforms ordinary fabrics into high-performing materials by altering their surface properties. From improved dye uptake to enhanced durability and functional features, these modifications play a vital role in modern textiles, setting the stage for innovations across apparel, medical, technical, and smart fabrics.

Table of Contents

Why Surface Modification Matters

Surface chemical modification of textile fibres is a crucial step in transforming ordinary fabrics into high-performing materials. Have you ever wondered why some clothes resist stains, maintain vibrant colors, or feel more comfortable? Surface chemical modification of textile fibres allows us to enhance durability, comfort, and functionality simultaneously.

The benefits are tangible:

- Improved dye uptake for longer-lasting, vivid colors

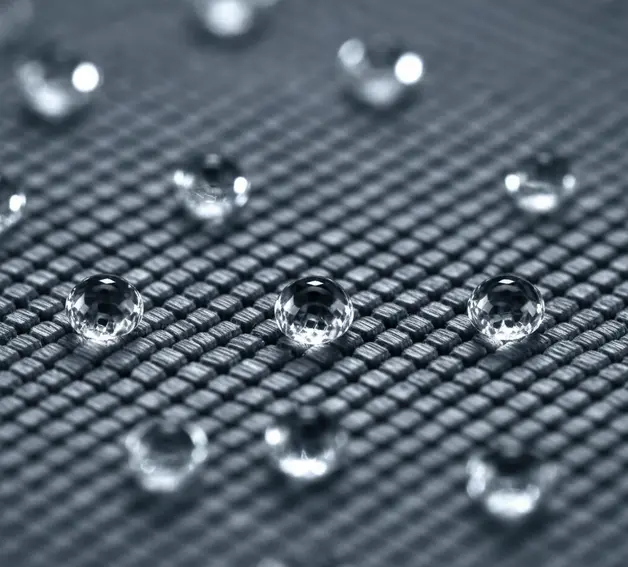

- Hydrophilicity or hydrophobicity control for moisture management or water resistance

- Antibacterial properties for hygiene-sensitive textiles

- Enhanced strength for durability and reduced wear

By embracing surface chemical modification of textile fibres, we move beyond basic fabric production, creating textiles that perform reliably and adapt to specific needs.

Key Chemical Techniques

When altering fibres chemically, several methods stand out: oxidation, grafting, plasma treatment, and crosslinking. Each serves a distinct purpose in enhancing fibre performance.

- Oxidation adds functional groups, improving dye absorption and reactivity.

- Grafting attaches polymers, giving fibres new functional capabilities without altering their core.

- Plasma treatment changes surface energy, boosting adhesion or adding antibacterial properties.

- Crosslinking forms molecular bridges that enhance mechanical strength and washing resistance.

| Technique | Effect | Common Use |

| Oxidation | Adds reactive groups | Dyeing, chemical reactivity |

| Grafting | Adds polymers | Hydrophobic or antimicrobial fabrics |

| Plasma | Alters surface energy | Coatings, adhesion improvement |

| Crosslinking | Strengthens molecular bonds | Durable apparel, technical textiles |

These methods offer a practical toolkit for customizing fibre behavior precisely and reliably.

Surface Chemical Modification of Textile Fibres: Explained

Surface chemical modification of textile fibres involves altering the outer layer at a chemical or molecular level to improve interaction with dyes, finishes, or external agents. Mechanisms like oxidation, grafting, plasma treatment, and crosslinking enable targeted changes without affecting the fibre core.

Think of fibres as sponges: modification doesn’t reshape them but changes how they absorb, repel, or interact with other substances. This controlled approach allows fabrics to meet performance requirements for color retention, moisture management, and functional treatments like antibacterial activity.

Enhancing Fibre Performance

Through surface chemical modification of textile fibres, we can significantly boost fibre properties:

- Durability: Crosslinking and grafting strengthen fibres against abrasion and washing.

- Hydrophilicity or hydrophobicity: Modified fibres wick moisture efficiently or repel water.

- Dye uptake: Better chemical affinity ensures vibrant, long-lasting colors.

- Antibacterial properties: Chemical treatments resist microbes and odors, essential for medical and sports textiles.

These improvements demonstrate how modification transforms ordinary fibres into high-performing, practical materials.

Practical Applications

The impact of surface chemical modification of textile fibres spans multiple industries:

- Apparel: Enhanced comfort, stain resistance, and color retention for everyday and activewear.

- Medical textiles: Antimicrobial and biocompatible fibres for wound dressings, gowns, and linens.

- Technical fabrics: Durable, flame-resistant, and chemically stable fibres for protective gear.

- Smart textiles: Conductive or responsive fabrics that interact with the environment or wearer.

By applying chemical modifications thoughtfully, industries can produce textiles that perform reliably and meet specialized demands.

Sustainability & Safety

Surface chemical modification of textile fibres can be environmentally responsible. Eco-friendly reagents, waste minimization, and water recycling reduce chemical impact. Choosing non-toxic or biodegradable chemicals protects workers and ecosystems.

Safety measures like proper ventilation, protective equipment, and monitoring chemical reactions are essential. Modification should improve performance without compromising ethical or environmental standards.

Adhering to a standard operating procedure for storing textile dye and chemicals helps minimize risks and ensures responsible usage.

Future Trends in Fibre Engineering

Looking ahead, surface chemical modification of textile fibres is driving innovation:

- Bio-based modifiers: Renewable chemicals enhance fibres sustainably.

- Nanotechnology: Nanoparticles add antibacterial, UV-protective, or water-repellent features.

- High-performance textiles: Lightweight, durable, and functional fabrics for aerospace, sports, and wearable electronics.

These trends show how chemical modification continues to expand fibre capabilities, creating textiles that are sustainable, interactive, and multifunctional.

Takeaways & Next Steps

Surface chemical modification of textile fibres transforms fabrics into durable, functional, and high-performing materials. Key points to remember:

- Performance matters: Improved strength, moisture behavior, dye uptake, and hygiene.

- Techniques are varied: Oxidation, grafting, plasma treatment, and crosslinking.

- Applications are broad: Apparel, medical, technical, and smart textiles.

- Responsibility is crucial: Safety and sustainability guide every modification.

- Innovation is ongoing: Bio-based modifiers, nanotechnology, and advanced fibres shape the future.

For researchers and industry professionals, the next step is clear: apply these chemical strategies wisely, and unlock the full potential of fibres for modern textiles. Surface chemical modification of textile fibres is not a trend—it’s a fundamental tool for creating textiles that meet today’s and tomorrow’s demands.

FAQs

What are the methods of surface modification?

Surface chemical modification of textile fibres can be achieved through oxidation, grafting, plasma treatment, and crosslinking. Each method adjusts the fibre’s surface properties to improve dye uptake, moisture management, durability, or functional features like antibacterial activity.

What are the surface modifications of natural fibres by various chemical treatments?

Natural fibres such as cotton, wool, and silk can undergo chemical treatments like oxidation to introduce reactive groups, grafting to add polymers, or plasma treatment to alter surface energy. These modifications enhance color retention, moisture behavior, and overall fibre performance.

What is surface treatment of fibres?

Surface treatment refers to chemically or physically altering a fibre’s exterior to improve its interaction with dyes, coatings, or finishes. Surface chemical modification of textile fibres is one form of treatment that targets performance, durability, and functional properties.

What is the surface modification of carbon fibres?

Carbon fibres are modified chemically to increase surface energy, improve adhesion to resins, and enhance mechanical bonding in composites. Techniques include oxidation, electrochemical treatments, and plasma exposure, all designed to optimize fibre performance for high-strength applications.