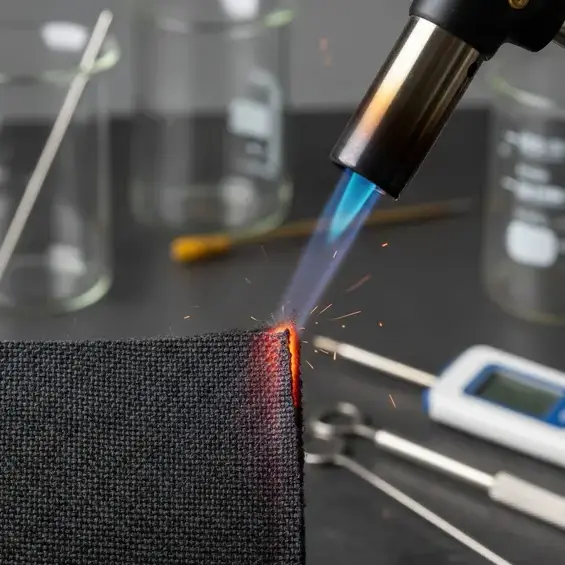

Fire retardant treatments for textiles involve applying chemical finishes that resist ignition and restrict fire development. These chemicals modify fiber structure or surface properties to resist ignition and self-extinguish flames. Their use is essential for meeting fire safety standards in apparel, upholstery, and technical textiles.

Key Takeaways

- Fire retardant chemicals reduce flammability and enhance safety.

- Common types include phosphorus, nitrogen, and inorganic salts.

- Used in protective wear, furnishings, and industrial textiles.

- Compliance with global fire standards is essential.

- Eco-friendly alternatives are emerging for sustainable production.

What Are Fire Retardant Chemicals for Textiles?

Fire retardant chemicals for textiles are flame-suppressing agents added during fiber manufacturing or finishing.

They function by:

• Forming an insulating char film to block heat transfer

• Interrupting oxidation and combustion mechanisms

• Emitting neutral gases that dilute burnable fumes

Examples: Phosphorus-based compounds, halogenated retardants, and nitrogen-based agents.

They are commonly used in polyester, cotton, and nylon fabrics for uniforms, curtains, and protective clothing.

How Do Fire Retardant Chemicals Work on Fabric Fibers?

These chemicals work through three main mechanisms:

- Gas Phase Action: Halogenated compounds release halides to inhibit flame radicals.

- Condensed Phase Action: Phosphorus-based agents promote char formation and insulation.

- Synergistic Systems: Combinations like phosphorus–nitrogen mixtures improve performance across fiber types.

For instance, ammonium polyphosphate enhances cotton’s flame resistance by promoting carbonization rather than combustion.

Which Chemicals Are Commonly Used in Flame Retardant Clothing?

Widely used fire retardant chemicals for textiles include:

| Chemical Type | Example | Primary Use |

| Phosphorus Compounds | Tetrakis hydroxymethyl phosphonium chloride (THPC) | Cotton fabrics |

| Nitrogen-Based Compounds | Melamine cyanurate | Polyester and blends |

| Halogenated Compounds | Decabromodiphenyl ether | Industrial applications |

| Inorganic Salts | Borax, Antimony trioxide | Coatings and blends |

These chemicals are selected based on fiber composition, end-use, and safety standards such as ISO 15025 and NFPA 701.

What Are the Main Applications of Fire Retardant Textiles?

Fire-retardant finishes are applied in:

- Protective clothing (firefighter suits, military uniforms)

- Home furnishings (curtains, carpets, upholstery)

- Transportation interiors (aircraft, train seats, and automotive textiles)

- Industrial fabrics (welding blankets, conveyor belts)

A textile chemical liquid is often discussed alongside flame retardant coatings, textile auxiliaries, and protective finishing agents used in industrial textile processing.

What Role Do Fire Retardant Chemicals Play in Compliance and Safety?

Regulatory compliance is central to the use of fire retardant chemicals for textiles.

They ensure materials meet international fire safety norms such as:

- BS 5867 (UK): Curtains and drapes

- ASTM D6413 (US): Vertical flame test for fabrics

- EN ISO 11612 (EU): Protective clothing for heat and flame

Manufacturers must also comply with environmental regulations limiting halogenated compounds under REACH and RoHS directives.

How Are Fire Retardant Chemicals Applied to Textiles?

Application depends on fabric type and desired durability:

- Durable finishes: Chemical bonding through pad-dry-cure methods

- Non-durable finishes: Surface coating or spray treatment for temporary use

- Inherent retardancy: Fibers manufactured with built-in resistance (e.g., modacrylic, aramid)

For example, cotton fabrics are often treated using THPC-ammonia processes to create permanent fire retardant finishes.

What Are the Environmental and Performance Considerations?

Modern formulations emphasize eco-friendly alternatives. Traditional halogenated systems are being replaced with phosphorus–nitrogen synergists, intumescent coatings, and nano-enhanced fire retardants that reduce toxicity and smoke emission.

The focus is shifting toward sustainable chemistry without compromising flame resistance or fabric comfort.

Conclusion

Fire retardant chemicals for textiles are essential for improving fire safety and maintaining regulatory compliance across industries. Their ongoing evolution toward eco-safe and high-performance formulations supports both safety and sustainability goals. For enhanced protection, related fabric technologies like uv protection chemicals textiles also contribute to overall material resilience.

FAQs

What chemicals are used in flame retardant clothing?

Common ones include phosphorus compounds like THPC, melamine derivatives, and boron-based additives.

What chemical is used for fire retardant?

Ammonium polyphosphate, boric acid, and halogenated compounds are frequently used.

How to use fire retardant on fabric?

By applying through a pad-dry-cure process or surface spraying, depending on fiber type and intended durability.

Are fire retardant chemicals safe?

Yes, when compliant with international environmental and toxicity standards such as REACH and OEKO-TEX.

Can fire retardant finishes wash off?

Durability varies; some finishes are permanent, while others require reapplication after several washes.

Sources

https://www.indiamart.com/proddetail/fire-retardant-chemicals-for-all-types-of-fabrics-14615935333.html?srsltid=AfmBOorwlCWOKB6w5BBzaUojJSnuOk7Ahubmj8FntRP4XhRPvw4P1ab_

https://www.sarex.com/textile/finishing-auxiliaries/flame-retardants

https://nctexchem.com/product/process/finishing/flameretardant/

https://en.wikipedia.org/wiki/Flame_retardant

https://www.marinefireretardant.com/fire-retardant-treatments-for-textiles/

https://www.slideshare.net/slideshow/fire-retardant-textiles/102693719

https://www.tradeindia.com/products/fire-retardant-chemicals-for-fabrics-c9583495.html