The chemical composition of textile dyes refers to the molecular structure and constituent compounds responsible for imparting color to fabrics. These dyes contain chromophores, auxochromes, and various reactive groups that determine their performance and compatibility with fibers. Why is this composition so crucial? Because it directly affects color fastness, dye uptake, and environmental safety during textile processing.

Key Takeaways

- Textile dyes derive color from chromophoric and auxochromic groups.

- Classification depends on molecular structure and fiber compatibility.

- Functional groups determine bonding and fastness properties.

- Support chemicals optimize dyeing uniformity and fixation.

- Sustainable dye selection aligns with global safety standards.

What defines the chemical composition of textile dyes?

Textile dyes are organic compounds characterized by specific functional groups that determine their coloration and fiber-binding properties.

Key components include:

- Chromophores – groups responsible for color (e.g., –N=N– in azo dyes).

- Auxochromes – enhance color intensity (e.g., –OH, –NH₂).

- Solubilizing groups – improve water solubility (e.g., –SO₃Na).

- In reactive dyes, the reactive moieties bond covalently to fiber surfaces, producing strong fixation..

Together, these elements control dye-fiber interaction, stability, and overall performance.

How are textile dyes classified based on chemical composition?

Dyes are categorized by their structural backbone and reactivity:

| Dye Class | Chemical Basis | Example Compound | Fiber Type |

| Azo Dyes | –N=N– groups | Direct Red 28 | Cotton, viscose |

| Anthraquinone Dyes | Quinone ring | Disperse Blue 56 | Polyester |

| Triphenylmethane Dyes | Aromatic amine derivatives | Malachite Green | Wool, silk |

| Sulphur Dyes | Sulphur linkage | Sulphur Black 1 | Cotton |

| Vat Dyes | Quinonoid structure | Indigo | Cotton |

| Reactive Dyes | Reactive functional groups | Remazol Blue | Cellulosic fibers |

Which chemical groups determine dye–fiber bonding?

The chemical composition of textile dyes includes specific functional groups enabling strong fiber attachment:

- Hydrogen bonds – found in acid and direct dyes.

- Ionic bonds – formed between cationic dyes and anionic fiber sites.

- Covalent bonds – present in reactive dyes, ensuring wash-fast color.

- In hydrophobic textiles like polyester, Van der Waals forces play a key role in disperse dye affinity..

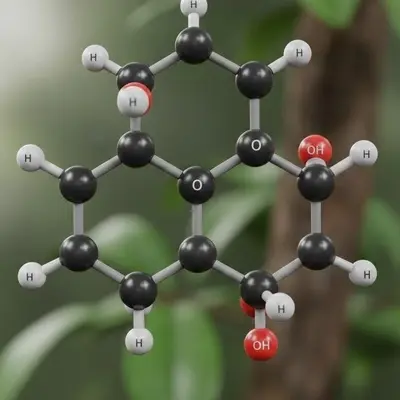

What are common examples of dye molecules and their structures?

Some representative examples include:

- Azo Dyes: Contain –N=N– double bonds; e.g., Congo Red and Methyl Orange.

- Anthraquinone Dyes: Based on anthraquinone skeleton; e.g., Alizarin.

- Indigoid Dyes: Derived from indigo compounds; e.g., Vat Blue 1.

Chemical liquids in textiles are often referenced along with pigment-based products, auxiliaries, and finishing chemicals for pre-treatment applications.

What chemicals are used in the dyeing process besides dyes?

Supporting chemicals enhance dye performance and processing consistency:

- Alkalis (Na₂CO₃, NaOH): For fixation in reactive dyeing.

- Acids (CH₃COOH): For pH control in acid dyeing.

- Electrolytes (NaCl, Na₂SO₄): Improve dye exhaustion.

- Dispersing Agents: Maintain dye stability in water.

- Levelling Agents: Ensure uniform color distribution.

These are part of the broader textile chemicals list essential for achieving high-quality dyeing results.

How does chemical composition influence dye performance?

The stability, brilliance, and ecological impact of dyes depend on their molecular composition:

- High molecular weight dyes yield better fastness.

- Reactive and azo dyes ensure vivid shades but may require controlled effluent treatment.

- Sulphur and vat dyes provide durability yet involve complex reduction chemistry.

Compliance with standards like OEKO-TEX®, REACH, and ZDHC ensures safe, sustainable chemical usage.

Why is understanding dye composition vital for modern textile production?

A detailed understanding of dye chemistry enables:

- Optimized shade reproducibility across batches.

- Reduced environmental load via low-impact formulations.

- Improved fiber compatibility and long-term performance.

It bridges laboratory research with industrial dyeing efficiency and sustainable innovation.

Conclusion

The chemical composition of textile dyes determines their functionality, fiber compatibility, and ecological footprint. Recognizing the interplay of chromophores, auxochromes, and reactive groups supports both product quality and sustainability. To explore related formulations, see the chemical composition of textile binder softener, which complements dye chemistry in textile finishing.

FAQ

What is the chemical composition of dyes?

It includes chromophores, auxochromes, and binding groups composed mainly of carbon, hydrogen, nitrogen, oxygen, and sulfur.

What chemicals are used in fabric dyes?

Common chemicals include azo compounds, anthraquinones, sulfur linkages, and reactive halides, along with auxiliaries like salts and alkalis.

What is the chemical composition of Red Dye 40?

Red Dye 40, or Allura Red AC, is an azo compound with the molecular formula C₁₈H₁₄N₂Na₂O₈S₂.

What are the main types of dyes in the textile industry?

Azo, reactive, vat, direct, acid, and disperse dyes are widely used depending on the fiber type.

Which factors affect dye stability?

pH, temperature, light exposure, and molecular structure influence dye stability and fastness.

Sources

https://tirumalaitextiles.com/types-of-dyes-in-textile-industry/

https://acmemills.com/industry-news-blog/list-of-chemicals-used-in-textile-dyeing-industry/

https://fineotex.com/helpie_faq/what-are-textile-dyeing-chemicals-and-what-are-the-functions-of-textile-dyeing-chemicals/

https://textilelearner.net/different-types-of-dyes-with-chemical-structure/

https://www.intechopen.com/chapters/41411

https://www.meghmaniglobal.com/different-types-of-dyes-with-chemical-structure/