Chemical used for textile dye removal from effluent plays a critical role in minimizing environmental damage caused by untreated industrial discharge. With rising regulatory pressures and ecological concerns, selecting the right treatment chemical isn’t just smart—it’s essential. Here’s a concise guide to methods, choices, and sourcing strategies that truly work.

Table of Contents

Why Dye Removal Matters in Textile Effluents

The chemical used for textile dye removal from effluent plays a pivotal role in protecting aquatic life, agricultural soil, and human health. Dyes in textile wastewater are not just unsightly—they’re toxic, persistent, and often carcinogenic. Would anyone want their drinking water tinged with azo compounds? Unlikely.

Discharging untreated effluent is like sending a poison pen letter to the environment. Poor removal hampers sunlight penetration in water bodies, disrupts photosynthesis, and throws ecosystems off balance. Effective dye removal isn’t optional. It’s critical.

Key Pollutants in Textile Wastewater

Before identifying the right chemical used for textile dye removal from effluent, it helps to understand what’s actually in that effluent. Spoiler: it’s more than just color.

Textile wastewater contains:

- Dyes: reactive, direct, vat, sulphur, and acid types

- Salts: sodium chloride and sulphate used in dye fixation

- Surfactants: from wet processing stages

- Heavy metals: chromium, copper, and lead from certain dye formulations

- Organic load: including formaldehyde-based resins and softeners

Each of these compounds complicates treatment and may interact with removal agents, making the right chemical selection more than guesswork.

Chemical Used for Textile Dye Removal

The chemical used for textile dye removal from effluent depends on dye type, effluent volume, and treatment setup. Some chemicals stand out due to reliability, cost-efficiency, and environmental footprint.

Common top choices include:

| Chemical Type | Examples | Target Dyes |

| Oxidizing Agents | Hydrogen peroxide, ozone | Azo, vat, sulphur |

| Coagulants | Ferric chloride, alum, PAC | Disperse, reactive |

| Adsorbents | Activated carbon, fly ash | Acid, direct |

| Reducing Agents | Sodium dithionite | Vat, sulphur |

Each chemical type targets dyes differently—some destroy them, others isolate and trap. The trick lies in matching dye chemistry with treatment chemistry.

These top choices highlight how targeted chemical action works best at the effluent treatment stage. For a comprehensive overview of each chemical used for textile dye removal—including use cases beyond effluents—read this extended breakdown.

Oxidizing Agents in Dye Breakdown

Among every chemical used for textile dye removal from effluent, oxidizing agents are the heavy lifters. They don’t just mask color—they break bonds.

Here’s how:

- Hydrogen Peroxide (H₂O₂): Generates hydroxyl radicals in the presence of catalysts or UV, cleaving dye structures irreversibly.

- Ozone (O₃): Reacts with unsaturated dye molecules at double bonds, fragmenting them into biodegradable pieces.

- Potassium Permanganate (KMnO₄): Less common due to cost, but highly effective against complex dye molecules.

These agents convert stubborn dyes into simple, less harmful molecules. But they work best in controlled conditions—pH, temperature, and contact time are all key.

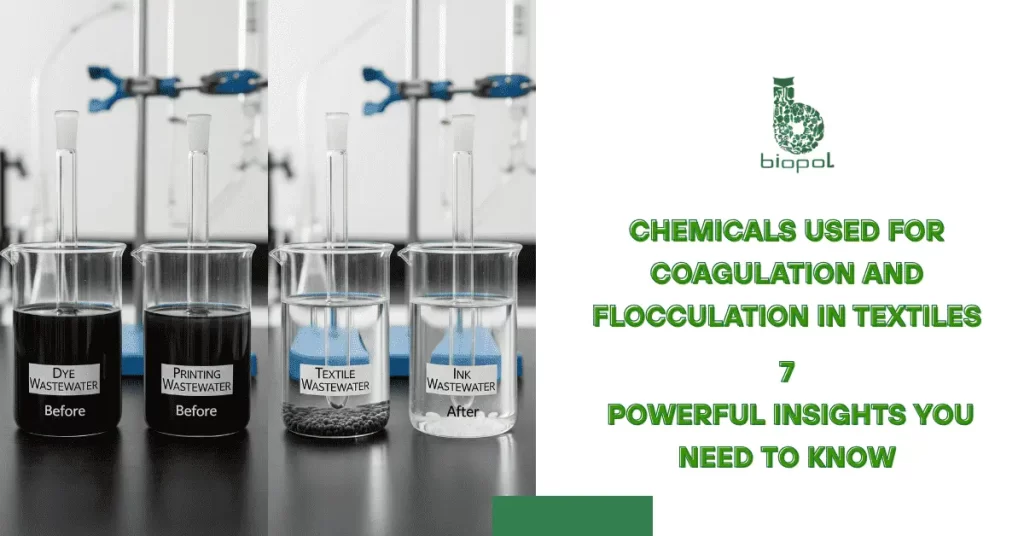

Coagulants and Adsorbents in Action

Coagulation isn’t magic, but it’s close. The chemical used for textile dye removal from effluent in this case works by destabilizing dye particles and binding them into removable clumps.

Typical coagulants:

- Ferric Chloride (FeCl₃): Effective but can increase sludge volume.

- Polyaluminum Chloride (PAC): Popular due to lower residual aluminum content.

Then come adsorbents, which trap dyes on their surface through van der Waals forces or pore entrapment. Activated carbon remains the gold standard, though alternatives like bentonite or fly ash are gaining traction for cost savings.

Coagulation followed by adsorption forms a one-two punch for colored effluents with high organic content.

Choosing the Right Chemical for Your Effluent

Selecting the most suitable chemical used for textile dye removal from effluent isn’t a roll of the dice. It’s chemistry matched with context.

Here’s what guides smart selection:

- Dye Class: Sulphur dyes respond better to reducing agents; azo dyes break under oxidation.

- Effluent pH: Some chemicals lose efficacy outside narrow pH bands.

- Sludge Management Needs: Ferric salts produce more sludge than PAC.

- Cost Constraints: Activated carbon is effective but expensive; fly ash may offer a budget alternative.

A well-planned jar test can save plants from long-term mistakes. Investing in lab-scale trials pays off in clarity and compliance.

Where to Source Effective Treatment Chemicals

Finding a dependable supplier for any chemical used for textile dye removal from effluent demands more than just browsing a catalogue.

Here’s what to ask:

- Is the chemical industrial-grade or lab-grade? Industrial batches should meet local discharge norms.

- Do they offer MSDS and application support? Safety and technical guidance are non-negotiable.

- Can they supply consistently? A one-time wonder isn’t a solution.

Local sourcing may reduce delivery time and cost, but international vendors may offer specialty chemicals unavailable domestically. The key is consistency and credibility.

Final Word

Choosing the right chemical used for textile dye removal from effluent isn’t just a regulatory checkbox—it’s a step toward clean rivers, sustainable operations, and brand credibility. Every chemical listed here has a place, but only one will match each plant’s exact needs. Let science lead, and let conscience follow.

FAQs

How do you remove dye from textile wastewater?

To remove dye from textile wastewater, industries rely on a combination of chemical used for textile dye removal from effluent, including oxidizing agents, coagulants, and adsorbents. These chemicals either degrade dye molecules or separate them for filtration. Techniques like advanced oxidation, electrochemical treatment, and activated carbon adsorption are widely employed for efficient decolorization.

Which chemical is commonly used for fabric dyeing?

The most common chemicals used in fabric dyeing include reactive dyes, acid dyes, and disperse dyes, each chosen based on the fiber type. These are not removal agents but colorants. Post-dyeing, however, chemical used for textile dye removal from effluent, such as hydrogen peroxide or sodium hypochlorite, becomes essential in treating leftover wastewater.

How is textile dye wastewater treated?

Textile dye wastewater is treated using a staged process—typically involving neutralization, coagulation-flocculation, and oxidation. Each phase applies a specific chemical used for textile dye removal from effluent to break down or separate contaminants. The process may also include biological and membrane-based systems for final polishing before discharge.

How do you treat wastewater containing dyes?

Wastewater containing dyes is treated by applying oxidizing chemicals like ozone or Fenton’s reagent to break down complex dye structures. This is followed by coagulants or adsorbents to capture suspended particles. The selection of chemical used for textile dye removal from effluent depends on dye type, effluent volume, and environmental compliance targets.