The chemical composition of textile binder softener refers to the combination of polymeric binders, emulsifiers, and softening agents used to enhance fabric handle, strength, and wash durability. These compounds play a pivotal role in textile finishing by ensuring pigment adhesion and fabric flexibility under varied processing conditions.

Key Takeaways

- Textile binder softeners combine polymeric binders with silicone-based lubricants.

- Functional groups like carboxyl and amino enable fiber bonding.

- Additives such as crosslinkers and thickeners improve performance.

- Eco-friendly formulations comply with modern textile safety standards.

- Crosslinking enhances softness and wash durability.

What is the basic chemical structure of textile binder softener?

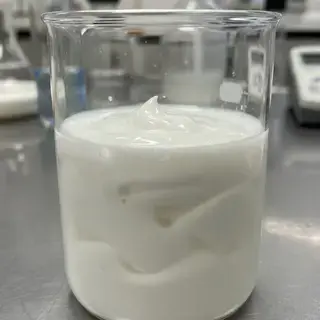

Textile binder softeners are typically composed of a polymeric backbone combined with functional softening agents.

Core chemical groups include:

- Acrylic or polyurethane binders: Provide film-forming properties.

- Silicone-based softeners (amino, macro, micro): Deliver smoothness and elasticity.

- Emulsifiers and surfactants: Maintain dispersion stability.

- Crosslinkers: Enhance adhesion and wash resistance.

In most formulations, these polymers contain carboxyl (-COOH) and amino (-NH₂) functional groups for chemical bonding with fibers.

How do silicone compounds influence the chemical composition of textile binder softener?

Silicone compounds, particularly polydimethylsiloxane (PDMS) derivatives, are crucial components.

They:

- Form a flexible hydrophobic layer on fabric surfaces.

- Reduce static electricity and improve hand feel.

- Increase abrasion resistance.

Example: Amino-functional silicones create ionic bonds with the binder matrix, ensuring superior softness without reducing color fastness.

What role do binders play in pigment fixation and durability?

Binders are the film-forming resins that hold pigments on fabric surfaces during heat curing.

Typical binder classes include:

| Type | Key Function | Common Composition |

| Acrylic Binder | Flexibility & transparency | Polyacrylate copolymers |

| Polyurethane Binder | Durability & elasticity | Polyisocyanate & polyol blends |

| Styrene-Butadiene Binder | Cost-effective adhesion | Copolymers of styrene and butadiene |

These binders form a crosslinked film network during heat fixation, locking pigments into the fabric structure.

What are common additives in the chemical composition of textile binder softener?

Industrial formulations also include performance enhancers:

- Antifoaming agents: Prevent foam during mixing.

- pH regulators: Maintain binder stability (usually pH 6–8).

- Thickeners: Adjust viscosity for screen or rotary printing.

- Preservatives: Improve storage life.

- Plasticizers: Add flexibility to the polymer film.

These ensure process consistency and compatibility with diverse textile substrates such as cotton, polyester, and blends.

How does crosslinking chemistry affect binder and softener performance?

Crosslinking strengthens the molecular network between polymer chains and textile fibers.

Key mechanisms include:

- Thermal crosslinking via melamine-formaldehyde or blocked isocyanate agents.

- Ionic interaction between carboxyl and amino groups.

- Hydrogen bonding with cellulose or polyester surfaces.

This enhances wash fastness, tensile strength, and surface smoothness without affecting breathability.

How is environmental compliance influencing modern binder softener formulations?

Due to REACH and OEKO-TEX regulations, eco-friendly binder softeners now emphasize:

- Formaldehyde-free polymers.

- Non-ionic silicone emulsions.

- Biodegradable surfactants.

Manufacturers are developing water-based dispersions to meet sustainability goals while maintaining softness and durability.

How does the chemical composition relate to other textile auxiliaries?

The chemical composition of textile binder softener is often discussed alongside textile finishing agents, coating binders, and printing emulsions, as these chemicals collectively influence fabric performance, feel, and print quality.

Conclusion

Textile binder softeners rely on a synergistic blend of acrylic, polyurethane, and silicone compounds supported by emulsifiers, plasticizers, and crosslinking agents. Their optimized chemistry defines the balance between softness, durability, and eco-compliance.

For deeper insight into sustainable chemical management, explore the role of poly chemical in treatment of textile wastewater — a vital step in modern textile processing.

FAQ

What is the chemical composition of fabric softener?

It includes cationic surfactants, silicones, emulsifiers, and conditioning agents that enhance softness.

What are the chemicals in fabric softener?

Common chemicals are quaternary ammonium salts, fatty esters, silicone oils, and fragrance carriers.

What are the ingredients for fabric softener?

Typical ingredients include water, cationic surfactants, emulsifiers, preservatives, and fragrance compounds.

What does fabric softener do chemically?

It reduces surface friction by forming a lubricating film over fibers, improving texture and flexibility.

Sources

https://patents.google.com/patent/WO2001025382A1/en

https://www.mohiniauxichem.co.in/silicone-textile-softeners-3092521.html

https://arihant-chemicals.com/softners/

https://textilefocus.com/textile-pigment-printing-chemistry-binders/

https://patents.google.com/patent/US20050039267A1/en

https://www.researchgate.net/publication/283538767_Organic_Silicone_Based_Poly-Acrylate_Binder_Synthesis_for_Textile_Pigment_Printing

https://www.venus-goa.com/finishing.php